|

How to

open up your faulty Logik IR100 Internet Radio to replace the rotary encoder

Before we start it must

be emphasised that all electronic devices are fragile and more so when they

are opened. In particular you must ensure that the radio is unplugged from

the mains (doh!) before you start. Inside the radio is a power supply board

on this are several capacitors. These are really batteries that hold a

charge (of several AMPS) for hours if not days. Many people do not believe

this but whilst a shock from a charged capacitor will not be deadly the

flash and loud crack when you accidentally short it out can easily cause

your screwdriver to slip resulting in serious damage to the radio – or you

if you stick it into your thumb! Fortunately you will not be dealing with

power supply faults (nor should you if you are inexperienced) so you can

heed this advice and move on.

WE DO NOT READ, NOR DO WE EVER FOLLOW INSTRUCTIONS

SUCH AS THESE. AFTER ALL WE “KNOW IT ALL”! IF YOU CHOSE TO GO AHEAD WITHOUT

HEEDING THESE WARNING THEN WHO ARE WE TO COMPLAIN – BUT DON’T SAY WE DIDN’T

WARN YOU!

The Logik IR100 Internet

Radio is made to a modular design with five or six different boards screwed

together with interconnections using ribbon cables that are plugged in. One

end of each ribbon cable is soldered into its circuit board and the other

has a plug which fits into a corresponding socket on another board. Once you

have the radio open the

first thing to do is look carefully where each plug goes – they can look

similar if you have not taken a careful look before starting. One idea is to

write on each cable with a unique mark try using a pencil or a felt tip.

There is also a loudspeaker plug which connects to the main power board.

This especially MUST be reconnected before reconnecting the mains or you may

blow the 8Watt amplifier.

It will immediately become

apparent that the construction of this radio is cheap – very cheap! For

example the end of each wire that is soldered into the board should use a

special connector which stops strain on the wire when you pull the plug on

the other end. On the Logik they have chosen to simply use some glue to

“reinforce” the soldered end! Pull too hard, or even flex the wire too much

and there is the real chance that you will break a wire inside the plastic

covering at the soldered end, so be gentle.

Experienced radio and

television engineers are well used to know how much they can pull a wire

without it breaking, if this is your first attempt at a repair then use the

rule of pulling just as little as you can and BE CAREFUL! IF you break a

wire then on no account reconnect the mains supply “to see if it still

works” as you run the real risk of damaging your radio. Mend the break

first! The micro controller board (which looks different to the others as it

is a different colour and well made) is really a small computer so break

that and expect a large bill to get it fixed – probably more than the radio

is worth!

Right, all the warnings out

of the way and if we haven’t put you off you can go ahead with the

instructions (or actually really suggestions) as to how you can get at the

encoder board to replace the rotary control.

The first job is to remove

the large knob on the front that is attached to the encoder that you are

later going to remove and then solder its replacement in to place. Some

people like to quite literally get the knob out of the way first; others

like to leave it until later. Either way this has to come off some time and

its removal is probably the hardest part of the whole repair. If yours does

not come away with a sharp tug or two perhaps wait a bit until later when we

will make some suggestions how to make the job easier.

As you will guess the

encoder is right at the front of the radio so as you go in from the back

there is a fair amount of stuff to move to get at it! First remove the six

screws holding the back on using a medium size cross head screwdriver that

is at least 15 cm long. Most screws will come straight out but at least one,

and probably more will get stuck in their mounting however much you turn

them. This doesn’t really matter and can be sorted out later. One suggestion

is to get a small pot to put all the screws in, you will probably end up

with up to 20 screws of different sizes before you start to reassemble so it

might be as well to mark them to make sure that you put the right screw back

into the right socket.

To help removing the back

you can put two fingers into the acoustic dome on the back to get some

purchase – do NOT pull on the mains lead, however much you want to, as it is

not well held - inside some sets it’s just glued in place! Don’t pull too

hard on the back either as there are three wires connected between the

modules fixed to the back cover and the rest of the set – pull these too

hard and you’ll break the wires! Also beware that some people have bought

“faulty” radios on eBay and found a collection of parts inside that are not

even plugged together – this has happened at least twice to our knowledge!

If you find any of the plugs out of their sockets then be very suspicious of

proceeding as if they are that deceitful the seller will obviously blame you

for the radio not working!

If you do decide to

continue then make sure that you have a full set of boards and not two the

same somewhere! The Barracuda computer boards are getting harder to find and

there will be a temptation to sell a non-working radio with this missing.

Right back to your “honest”

radio. Having pulled the back perhaps an inch or so away carefully look

inside the radio and you will see two ribbon cables and one loudspeaker

cable stopping your pulling any further. Before proceeding follow our

earlier recommendation to look carefully at which plug goes into which

socket and write it down somewhere. Two of the cables plug into sockets

on boards attached to the back, and one cable has its plug end inside the

set. All we can suggest is that you carefully try to separate these plugs

starting with the two on the back of the radio. There is some “nail varnish”

type stuff which is meant to hold the plugs together – it doesn’t – but it

does help show you which way round to reassemble the cables later. To

separate try putting your nail under the plastic lip of each plug and socket

combination but try not to pull on the cable itself. Do make sure you’re

careful or you’ll not have a working radio after all your trouble! Once you

have the three connectors separate you are now able to move the back away

from the set.

Next look underneath the

set at the front and you will see a single screw – this is the only

countersunk screw in the radio so don’t lose it as you can’t swap it with

anything else when you put it back together. Remove this screw and you may

see a red spacer underneath, if so pull that out and store both safely in

your pot.

The front of the set will

now come away quite easily (the glue holding it will have dried up) and you

will be left with the empty wooden case in one hand and the front panel in

the other. If you decided to leave levering off the large knob earlier then

you can put it off no longer, so put something onto the plastic to reinforce

and act as a fulcrum as well as saving too much damage to the plastic, then

with your flat bladed screwdriver lever the large knob off. You are aiming

for the screwdriver to engage with the centre of the knob, not the edge

which is very thin and will crack with too much pressure. The knob WILL

come, but may take a lot of persuasion and some ingenuity to remove. Just

keep trying, it’s only plastic! Perhaps try putting something slim and

strong to lever against? Sometimes these knobs just drop off (quite

literally) as they are only held with a bit of double sided tape, others are

held like they have been held on with epoxy resin. There is unfortunately no

way out of it, if you want to replace the encoder then to get inside the

knob MUST come off - by fair means or foul! Next pull off the volume knob

(usually much easier) and you can start to breathe again.

Put the front face down on

something to save it getting scratched (a pillow or some foam perhaps?) and

start disassembly. Fortunately you do not need to remove all the screws that

you can see! There are six to take the bracket that holds the display and

other boards off, two are located at the very bottom where they screw

through the grey plastic, one is on the edge beside the “dogleg”, and

another three at the top. Yes three! In the very corner at the edge is what

looks like an ordinary screw but it is about 4 times the length of all the

others so keep twiddling! There is one other normal length screw in the

other corner and then one more that is hidden under the cable at the top.

You don’t need to unplug this cable (at all) just push it gently over and

remove the screw. The whole module will now come away in your hand.

Turn it over and you will

see the boards with the buttons, controls, and the display – be very careful

and do not be tempted to clean the display as it is not made of normal

plastic. It is quite soft and marks easily and permanently, leave it well

alone! If you MUST remove a bad mark try alcohol and don’t rub too hard.

All you need do now is

remove the four short screws that hold the control board in place. You will

see two ribbon cables coming from the control board. One goes through the

slot and leads right to the back of the set – you must replace the wire

through the slot, and the other just goes under the wire leading to the

micro control board. This plug needs removing – gently – and make sure than

when you come to reassemble you put the wire back under the other. If you

don’t keep the cable dressing the same there is a chance that one will get

snagged by the case when you come to reassembly. I have done this and broke

the cable.

So after two pages of notes

you finally have the board that you need in your hand – time to warm up your

soldering iron!

There are (at least) two

different styles of control board – one original and one modified. Look at

the photos to see if your board is the modified variety as some people have

found that their replacement encoder works better when the modification is

removed. It’s up to you but you might choose to check both ways.

If you do want the

modification removed then you will need to take away two resistors

(cylindrical components with colour code) and then BRIDGE where they were

with pieces of wire. You are replacing the resistors with wire NOT joining

where the components were together – hope that’s 100% clear! Also remove the

extra capacitor (small brown flat round component) that is next to them.

There is a further component in the mod which is a capacitor near where the

wire leaves the board. This can stay as it’s difficult to remove but if you

wish to by all means do have a go at removing it, entirely at YOUR risk!

Next you need to “simply”

unsolder the old rotary encoder using a solder sucker or desoldering braid.

Clean the position and replace with the new encoder. Do be aware that the

circuit board is of rubbish quality and it is extremely easy to break one or

more of the tracks (often invisibly) when you apply heat so get your test

meter out and check now, then check again! We have broken tracks even after

knowing all this and the breaks are often at the edge of the etching where

the modifications have been soldered over. That’s a break underneath the

soldering which is not connected - really, really nasty!

If your original encoder

did work after a fashion then it might be an idea to desolder it carefully

and put is aside safely so if something goes wrong you at least have

something to replace to test and see where the problem lies. You could even

try opening up the encoder by bending the clips, clean the four contacts

with some alcohol, clean the track and reassemble. Until we obtained the

replacement encoders that was all that you could do!

After resoldering and

checking it’s time to put your radio back together. Now it’s not for us to

suggest this but you might prefer to leave the knobs off for now and put the

parts back together with the minimum number of screws to check that your

radio works before tightening everything together. Up to you and WE did not

suggest this – be careful if cutting corners. Be especially careful not to

trap the ribbon cables. Break these internally and expect many hours of

checking and frustration!

Replace the plugs into

their respective sockets making sure you put each in the right way round. It

is hard but not impossible to put them in backwards! This is where marking

the plugs before disassembly will have helped, if unsure better to wait and

ask someone (even us) than ruining your radio at this stage. If after

reassembly you find the small black buttons on the front either don’t work

at all or need pressing much harder than before to click, you will need to

reopen the set and look at the rubber mat which should sit neatly in its

place between the buttons and the electrical switches. You will find the mat

has moved or perhaps even dropped on the floor without your noticing!

The large knob will next

require your attention. If you have been sent an encoder with a round metal

spindle then the knob will need very slightly enlarging before it will fit.

We use a 6mm drill bit held in a pair of pliers and give a couple of

twiddles - in a drill would be too much and would remove too much plastic.

The plastic is very, very cheap (so what else is new) and you will only need

a couple of turns of your drill to make the knob fit. If you drill too much

away don’t worry, a little hot melt glue, or even a piece of sellotape will

hold it fine and you will know that next time you fix your radio (as if) you

will not have so much difficulty getting it off!

It was discovered early

on that the encoder was not really up to the job so some radios were

modified in production to stop the encoder causing clicking on the audio

when turned and to possibly also make the cheap component last longer. This

obviously did not work! If you wish you can try removing the modifications

which had a down side effect of making selection slower and less accurate

because they "rounded the edges" of the pulses generated by the encoder.

DO NOT REMOVE THE

MODIFICATION IF YOUR NEW ENCODER IS WORKING OK

|

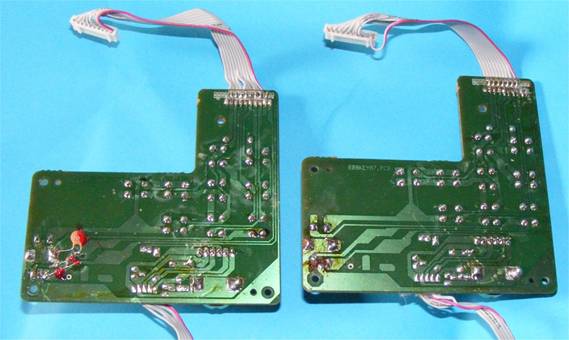

The two boards compared, modified on the left, unmodified on the

right.

The extra components on the modified board can be clearly seen, bottom

left.

On some sets (not shown here) there is also an extra chip capacitor in the top right corner near

the connector,

it's hard to remove without damaging the circuit underneath so best to leave it alone. |

|

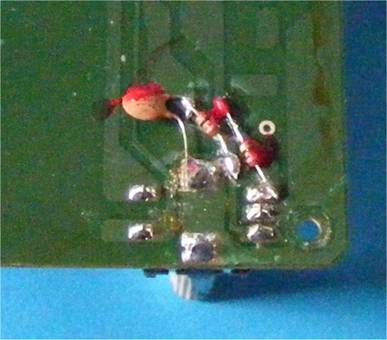

Close up of the three components that may need to be removed.

The two resistors that may need to be replaced with wire links are on

the right.

The capacitor can just be removed.

|

|

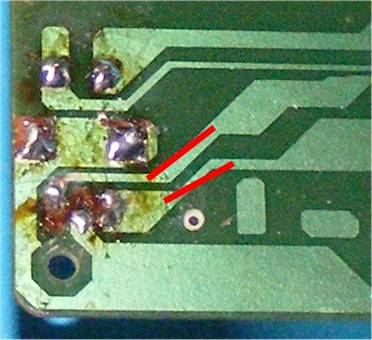

An unmodified board showing the original connections and the

approximate positions of where you may need to add two wire links to

replace the removed circuit copper tracks on modified boards.

The “mess” of flux is original and shows the poor quality of

manufacture.

Beware that the construction is awful and the metal tracks extremely

thin and fragile. They may peel away and need gluing down or replacing

with wire links. This applies to the entire radio except the Barracuda

board.

|

|

The unmodified connector end where an extra chip capacitor may have

been soldered.

Because of the size and difficulty it is probably best to leave the

extra capacitor

(which if fitted would be on the right hand end above the “C86” label)

alone.

There are extra circuit tracks under this printing which makes

removal difficult.

|

|